|

|

|

|

|

|

| Helps raise productivity in casting with new simulation based on the particle method |

TOKYO, May 25, 2017 - (JCN Newswire) - Fujitsu Limited and Daido University Professor Yasuhiro Maeda have jointly developed new simulation technology that can accurately replicate splash and wave behavior in the surface of molten metals when they are being poured.

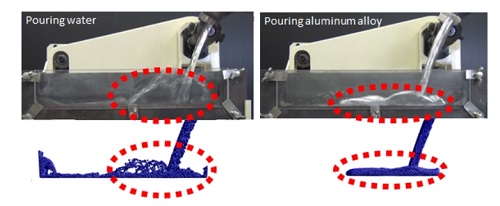

| | Figure: Trial of the simulation technology in comparison with a pouring experiment with Die Casting shot sleeves: The simulation (below) correctly replicates the differences in motion of water and aluminum alloy, observed in the experiment (above). |

In the casting process, which is used in component manufacturing in a variety of fields, such as automobiles and IT devices, molten metal is poured into a mold to be cast into a shape. The way molten metal flows through the interior of a mold significantly effects casting quality, but because the interior is impossible to see, there has been a demand for a simulation that can clarify how molten metal flows within the mold. However, simulation of this flow has been difficult to achieve as the way molten metal flows can change greatly depending on the oxide film that forms when metal contacts the air.

Now, based on a simulation technology known as the particle method(1), Fujitsu and Daido University have developed a new way to calculate flow variations with physical properties (viscosity) near the boundary between it and the air. This technology was then verified, comparing it to an actual experiment modeling a process where aluminum alloy melted at high temperatures is poured into casting equipment, which confirmed that the manner of splash suppression in line with the oxide film on the poured liquid metal could be accurately simulated.

This technology creates a simulation to clarify how molten metal flows inside casting equipment and molds, a process which cannot be observed from the outside. This will make it possible to change metal pouring procedures so as to more quickly manufacture high quality products, which is expected to contribute to improving casting productivity.

Details of this technology will be announced at the 169th JFS Meeting (Japan Foundry Engineering Society), which will be held on the Setagaya campus of Tokyo City University on May 26-29.

Background

Casting, which is used in the manufacturing of components for a variety of fields, including automobiles, appliances and IT devices, is a process in which metal that has been melted at high temperatures is injected into molds, and the way the metal is injected is known to have a significant impact on the quality of the component. In a casting method known as Die Casting(2), for example, if the liquid metal inside the shot sleeves that inject the molten metal into the die at high pressure violently splashes, oxides or other impurities that form on the surface where it meets the air can be mixed in, leading to the casting defects in the shaped component that make them prone to breakage. For this reason, in order to prevent severe splashing of the liquid metal surface within the shot sleeve, the timing of the injection into the mold is adjusted based on estimates of the splashing of the liquid surface in the parts of the sleeve that cannot be seen, creating a need for technology to accurately simulate how the liquid metal flows.

Issues

Metal that has been melted at high temperatures reacts with oxygen the instant it comes into contact with air, generating an extremely thin oxide film less than 0.1mm on the surface, which greatly reduces fluidity. For this reason, it was not possible to get accurate results with previous commonly used technology, which simulated it as the flow of a uniform liquid. In order to calculate the impact of the thin oxide film formed as the liquid surface splashes, it was necessary to separate out the thin film for calculations using a technology that can simulate the splashing. In order to calculate at the extremely high rate of precision that enables distinguishing the thin film, however, computations of over one thousand times greater than that of a uniform liquid simulation would be necessary, meaning timely simulations were not realistic.

Overview of the New Simulation Technology

Fujitsu and Daido University have developed simulation technology that can calculate the impact of lowered fluidity in liquid metals due to the thin oxide film without significantly increasing computation cost. This technology combines a method known as the particle method, in which fluids are represented as collections of particles in calculations, with a new computational model that dynamically changes the physical property values of particles located on the surface of the liquid. With this computational model, the physical property values related to fluidity (viscosity) for the particles located on the liquid surface are set based on the ratio between the size of the particles representing the liquid metal and the thickness of the film. Because the impact of lowered flow properties due to the formation of the thin oxide film can be calculated with this method without changing the particle size, which is the base unit of calculation, the computational time required for the simulation can be kept to about the same level as a simulation of a flow of a uniform liquid.

In a technology trial in which the simulation was compared with an experiment modeling the pouring of aluminum alloy melted at high temperatures into a Die Casting shot sleeve, it was confirmed that a simulation that correctly reproduced the way molten metal flows, which is significantly different from water, could be accomplished in about eight hours of computational time (see figure).

http://www.acnnewswire.com/topimg/Low_FujitsuDaido.JPG

Figure: Trial of the simulation technology in comparison with a pouring experiment with Die Casting shot sleeves: The simulation (below) correctly replicates the differences in motion of water and aluminum alloy, observed in the experiment (above).

Future Plans

Fujitsu aims to commercialize this newly developed simulation technology in fiscal 2018.

(1) Particle method

A mathematical computation method that represents liquids as accumulations of numerous particles. It is used to analyze phenomena such as the complex shape-changing behavior of the surface of water.

(2) Die Casting method

A casting method in which molten metal is injected into metal molds (dies) at high speed to make cast objects. It offers the ability to mass produce components with precise shapes, so it is widely used to manufacture components for automobiles, appliances, IT devices, etc.

Contact:

Fujitsu Limited

Public and Investor Relations

Tel: +81-3-3215-5259

URL: www.fujitsu.com/global/news/contacts/

Topic: Press release summary

Source: Fujitsu Ltd

Sectors: Enterprise IT

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

|