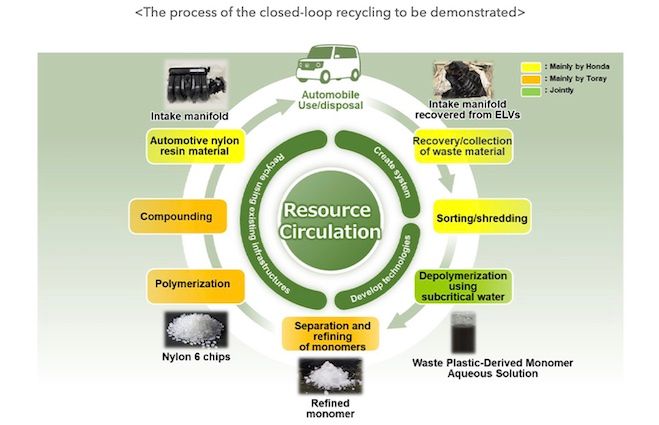

Honda R&D Co., Ltd. (Honda) and Toray Industries, Inc. (Toray) have begun a joint demonstration related to closed-loop recycling(1) of the Nylon 6 resin(2) ("Nylon resin") recovered from End-of-Life Vehicles (ELVs).

This joint demonstration is certified by the Japanese Ministry of the Environment (MOE) as a part of its project to establish a decarbonized circular economy system(3). Honda and Toray will install and verify a pilot facility with a processing capacity of 500 metric tons of resin per year, with the aim of putting this recycling process into practical application by around 2027.

As evidenced by the enactment of the Plastic Resource Circulation Act, societal demand for the recycling of not only beverage containers and clothing but also waste plastics has been growing in recent years in Japan. However, until now, the treatment of automotive nylon resin waste has been limited to the recovery and utilization of heat energy generated during incineration, due to the technical difficulty of sorting, collecting, and recycling.

Against this backdrop, Honda and Toray have jointly succeeded in monomerizing recovered nylon resin back to its molecular state using subcritical water(4). The use of subcritical water as a solvent has been proven to result in the recycling of nylon resin in a shorter time, with a higher yield(5) and less environmental impact compared to the process using conventional acid catalysts. Applying this technology in this joint demonstration, the two companies will verify the recycling of intake manifolds recovered from ELVs in Japan and strive to establish a closed-loop recycling process to generate recycled material with the equivalent performance and quality as a virgin material.

Key features of the nylon resin closed-loop recycling technology Honda and Toray will verify

It is possible to produce monomers, a raw material for engineering plastics(6), directly from the recyclable material.This monomer production method which uses water as a solvent enables more environmentally responsible and efficient monomer production, taking only one-fifth the time, compared to the method using conventional acid catalysts.

This technology is expected to be applicable to monomerizing materials for engineering plastics other than nylon resin. Through this joint demonstration, the two companies will verify how effectively their recycling technology can contribute to a circular economy when applied to a broader range of materials, including non-automotive parts, such as clothing and film, mainly in Japan.

Honda has identified "resource circulation" as one of the key directions to focus on in order to future advance its mobility products. Through various partnerships and collaborations, such as this one with Toray, Honda will proactively utilize recycled resources and continue striving for the realization of "zero environmental impact."

(1) A recycling process where post-consumer products are recycled to supply the material used to produce a new version of the same type of product.

(2) A type of nylon resin Its excellence in strength, heat resistance and chemical resistance makes Nylon 6 suitable for automotive parts that are often exposed to heat, gasoline and automotive oils.

(3) Ministry of the Environment fiscal 2023 project to establish a decarbonized circular economy system (including the Demonstration Project for a Plastic Resource Circulation System)

(4) The high-temperature and high-pressure liquid water at a temperature and pressure slightly below the critical point of water (374 degC, 22 MPa).

(5) The ratio of the quantity of target substance actually obtained in relation to the theoretically expected quantity when extracting the target substance from the raw material substance in a chemical reaction.

(6) Plastics with excellent mechanical strength, heat resistance and abrasion resistance, widely used for components of machinery, automobiles, electronic equipment, and other products.

About the demonstration project

Project name: Ministry of the Environment fiscal 2023 project to establish a decarbonized circular economy system (including a Demonstration Project for a Plastic Resource Circulation System)Ministry news release link (in Japanese only) https://www.env.go.jp/press/press_01945.htmlProject period: From July 2023 – March 2026 (tentative)Project representative: Toray Industries, Inc.Joint demonstration partner: Honda Motor Co., Ltd.

Topic: Press release summary

Source: Honda Motor Co, Ltd

Sectors: Automotive

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|