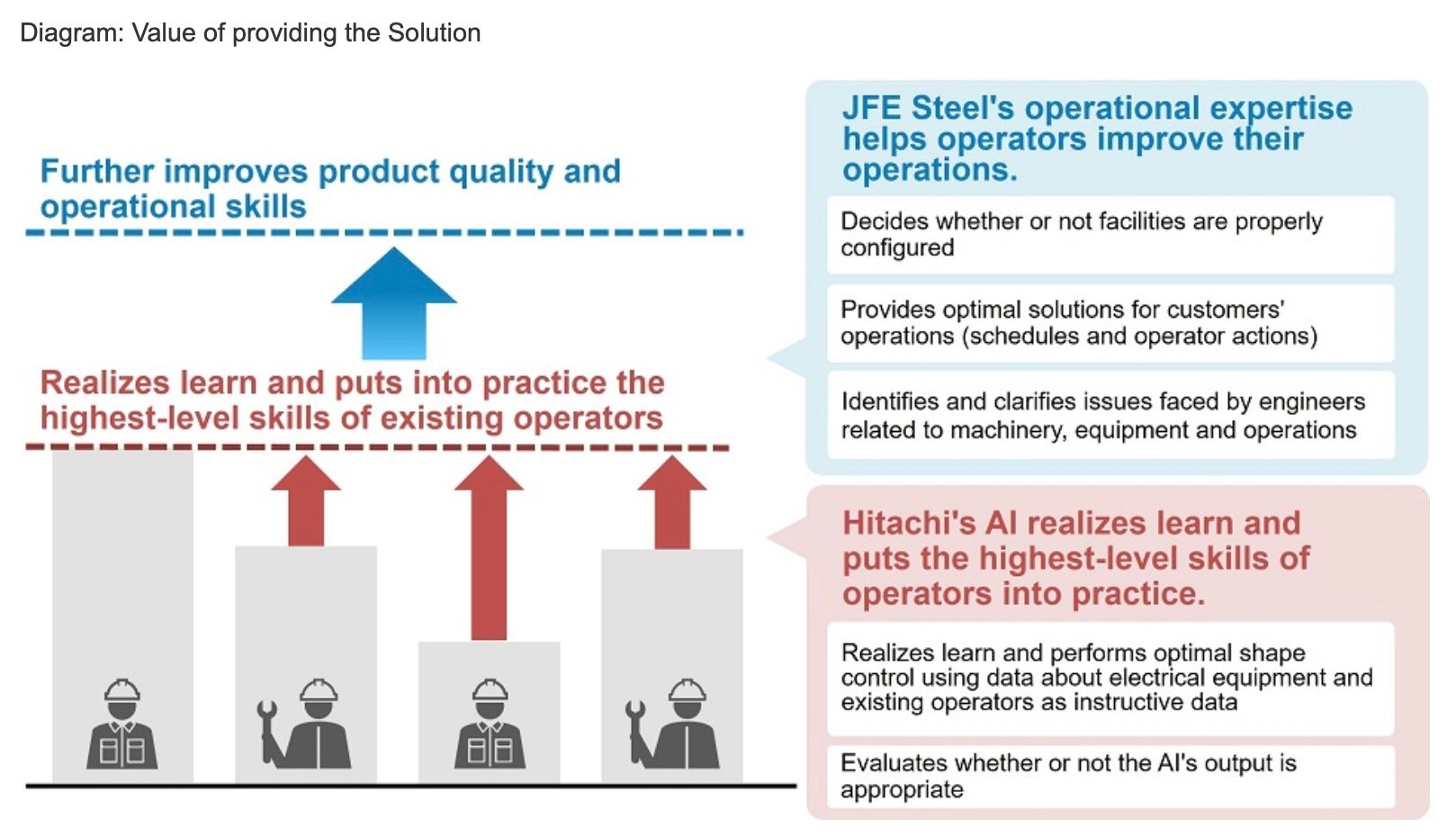

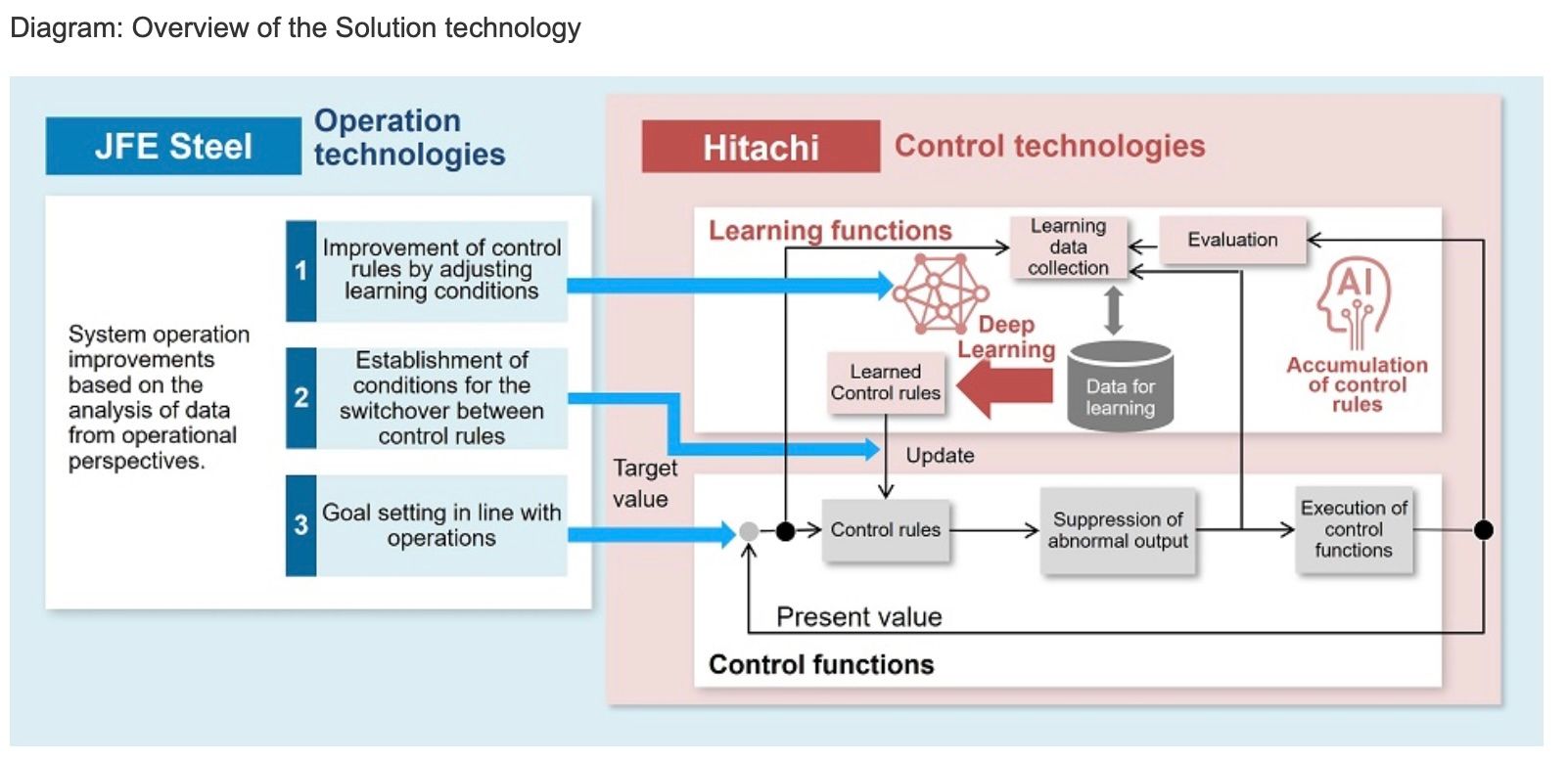

TOKYO, Mar 26, 2024 - (JCN Newswire) - JFE Steel Corporation ("JFE Steel") and Hitachi, Ltd. (TSE:6501, "Hitachi") today announced that they have started to provide a solution (the "Solution"), which combines JFE Steel's consulting programs and Hitachi's automatic cold-rolling flatness control system, to steel companies in both Japan and overseas. The Solution features the combination of Hitachi's system, which uses an artificial intelligence (AI) to automatically control the steel sheet flattening process by a rolling mill, and JFE Steel's consulting programs (regarding the introduction of systems and optimal operations), a service that leverages its high-level operational expertise in ways that meets customer needs.Traditionally, wavy steel sheets are flattened by a rolling mill that must be finely adjusted manually by skilled operators. The Solution will address relevant issues such as the deterioration of yields due to differences in operators' technical skills and the transfer of expert skills, and in addition, help customers improve their skills and product quality.

The JFE Group has been working to improve production efficiency and yields and drastically enhance labor productivity through the DX-driven introduction of new technologies. In addition, it has been promoting a solution business to provide a broad range of customers engaging in manufacturing businesses with methods for producing high value-added products, which the Group has developed through the operation and management of steelworks, and technological, operational and research expertise to address issues related to facility maintenance and environmental load reduction.

Hitachi has been offering Lumada*1 solutions to accelerate DX by leveraging products, OT (operational technologies) and IT, which it has developed over many years as a manufacturing company, as well as a wealth of knowledge and expertise (domain knowledge) that it has acquired through the provision of solutions to issues faced by customers operating in broad areas and domains in the manufacturing industry. In the steel business area, it has been globally promoting facilities, process lines, control systems and other equipment for plants as a comprehensive system.

Background

The transfer of operators' skills is a major issue on the front lines of the steel manufacturing industry, in which a generational change is underway. To flatten wavy steel, which occurs at each side or in the center of a steel sheet during the manufacturing of steel sheets, it is necessary for the operator to measure waviness and implement feedback-based control while simultaneously manually making fine adjustments. Inexperienced operators find it difficult to manufacture products with different shape accuracy and quality requirements compared to skilled operators, which can lead to poor product yield and breakage issues due to shape defects. To address such issues, Hitachi developed a technology that automatically performs high-quality shape control in 2017*2, which features a process in which AI learns the relationship between operational data about highly skilled operators and data about the shapes of steel sheets, enabling the results of this learning to be reflected in the output of the control system. It has been providing the technology as an automatic cold-rolling flatness control system in Japan and also overseas. JFE Steel introduced the system on its production lines in 2021. Since then, it has been achieving a great deal, such as improved product yields, higher utilization rates and reduced operator workload through automation. Moreover, enabling the operational knowledge and expertise of skilled operators to be reflected in automated processes led to increased productivity and the stabilization of product quality through the prevention of problems.

Building on these results, JFE Steel and Hitachi started to provide the Solution combining the two companies' strengths with a view toward addressing the issues faced by their customers in cold-rolling-based manufacturing. The two companies will work together to consider the configuration and make adjustments to the system that is optimal for customers' installation.

(1) Lumada: A collective term for solutions, services and technologies based on Hitachi's advanced digital technologies for creating value from customers' data accelerating digital innovation

(2) Hitachi, Ltd. news release titled "Hitachi Develops Real-Time Control Technology of Cold Rolling Plants for Steel Plants Using AI" announced on October 31, 2017.

Contact:

JFE Steel Corporation

Contact Us (msgs.jp)

Hitachi, Ltd.Business Contact

Inquiry form: Industry

Topic: Press release summary

Source: Hitachi, Ltd.

Sectors: Metals & Mining

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|