TOKYO, June 19, 2024 - (JCN Newswire) - Hitachi Industrial Equipment Systems Co., Ltd. today announced it has launched the "Predictive Diagnosis Service" for air compressors used as power sources for factory equipment, etc. The service uses machine learning to analyze data obtained through remote monitoring and combines it with the knowledge accumulated by Hitachi Industrial Equipment Systems maintenance staff to detect and prevent problems and abnormalities that could lead to equipment stoppages in advance. This service also uses the expertise of maintenance staff to estimate the effects of factors that reduce operating efficiency and can propose more efficient operations with less environmental impact.

Background of New Service

To ensure the stable operation of air compressors, specialized technicians are needed to perform maintenance and inspections. However, due to the declining birthrate and aging population, the number of technicians is decreasing, and there is an urgent need for remote maintenance management and more efficient operations. In addition, from the perspective of preventing global warming, there is a growing need to reduce environmental impact by operating equipment more efficiently with lower power consumption.

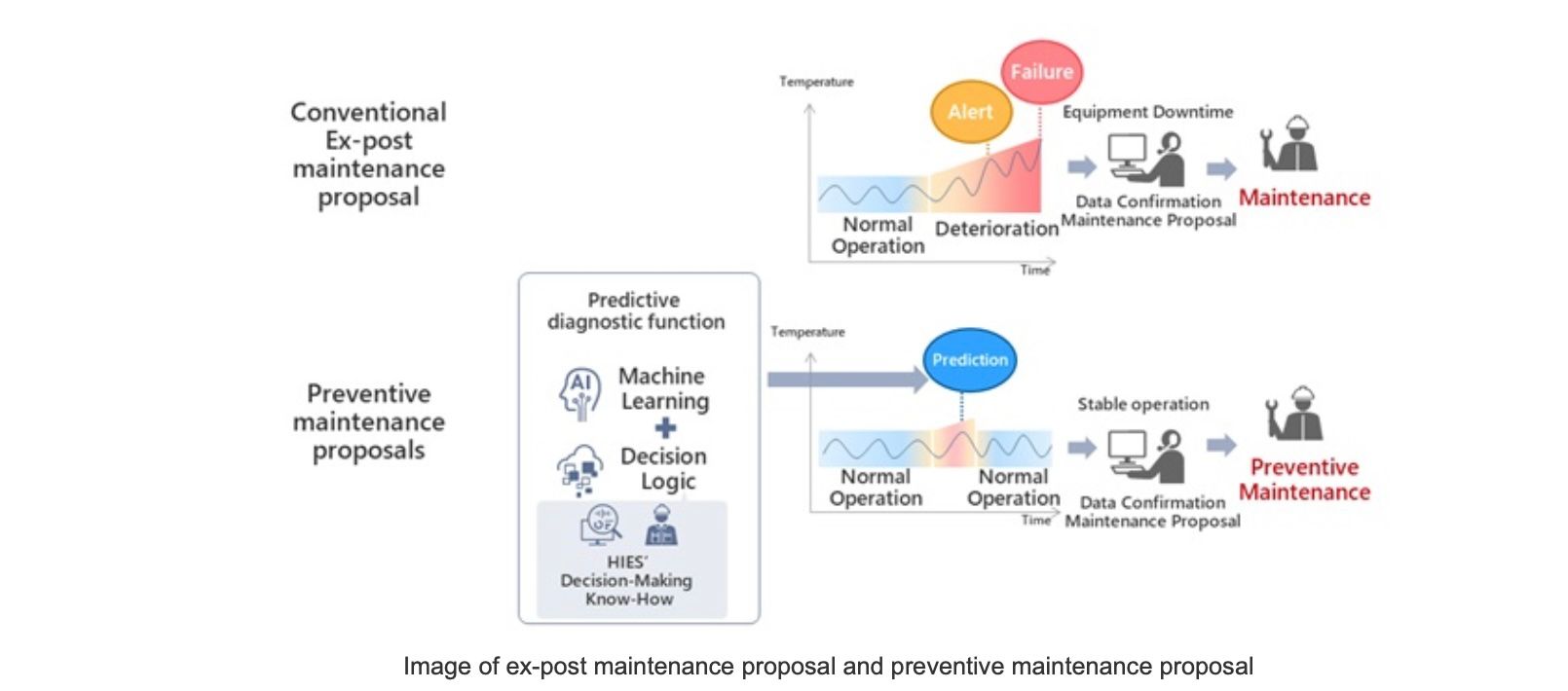

Since October 2017, Hitachi Industrial Equipment Systems has offered FitLive*, an equipment monitoring service, which reduces the equipment downtime by monitoring the operating status of each product remotely and automatically sending alerts when problems occur. Analysis of FitLive data for air compressors has revealed that temperature-related alarms and malfunctions account for approximately 75% of all alarms and malfunctions. Therefore, we developed a predictive diagnostic service that uses machine learning to estimate the future effects of temperature rise trends detected by sensors and take preventive measures against malfunctions.

*Equipment monitoring services provided by Hitachi Industrial Equipment SystemsFeatures of the Service

This service systematizes the decision-making know-how accumulated by Hitachi Industrial Equipment Systems' maintenance staff during their maintenance management work and uses it as a basis for decision making.Predictive diagnostics are performed by a combination of machine learning and know-how, and the results and the factors on which the estimation is based are displayed. In the past, maintenance staff made inferences and provided consulting based on the data they had obtained, but this service enables maintenance staff to make more specific and effective proposals by automatically performing predictive diagnosis.The data can also be used to identify cases in which the performance of an air compressor tends to deteriorate, such as when the ambient temperature of the air compressor is high or the filter needs to be cleaned, and to propose more efficient operation methods.

Currently, this function is only available for the 22/37kW inverter type oil-injected screw air compressors of the NEXT3 series, but the number of applicable models will be expanded in the future. Through the expansion of this service, we will provide more detailed and speedy preventive maintenance proposals to minimize air compressor outages, reduce energy consumption, and propose operations that help reduce environmental impact.

About Hitachi Industrial Equipment Systems

The Hitachi Group is promoting the Social Innovation Business, which uses data and technology to realize a sustainable society. As part of "Connective Industries," which provides solutions by digitally connecting products in a wide range of industries, Hitachi Industrial Equipment Systems provides products and services for industries such as air compressors, power distribution transformers, and motors. Under the phrase "Leading a Sustainable Future," Hitachi Industrial Equipment Systems aims to contribute to solving issues faced by customers and society by providing green products with low CO2 emissions and high efficiency and digitally connected products. For more information, please visit the Hitachi Industrial Equipment Systems website (https://www.hitachi-ies.com/).

IR Inquiries:

6-6, Marunouchi 1-chome, Chiyoda-ku, Tokyo, 100-8280

TEL : +81-3-3258-1111

ir.info.hq@hitachi.com

Topic: Press release summary

Source: Hitachi, Ltd.

Sectors: Manufacturing

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|