|

|

|

|

|

|

| Providing larger current and higher reliability for use in electric vehicles, hybrid vehicles and smart grids |

TOKYO, May 29, 2012 - (ACN Newswire) - Tanaka Denshi Kogyo K.K. (*1), which boasts the world's leading share in bonding wire manufacturing, today announced that New Japan Radio Co., Ltd. had adopted Tanaka Denshi Kogyo's "CHA" thick copper wire for wiring on aluminum electrodes of semiconductor chips manufactured by New Japan Radio. This has led to the establishment of the world's first (*2) power semiconductor mass production technology using copper wire.

| | World-first Replacement of Power Semiconductor Wire with Copper for Mass Production; Tanaka Precious Metals Introduces Thick Copper Wire for New Japan Radio |

New Japan Radio has conducted research and development with the aim of providing high reliability and reducing the burden on the environment as product technologies for applications requiring high voltage and large currents, such as industrial equipment, electric vehicles (EV), hybrid vehicles (HV) and smart grid (next-generation power grid) power transmission. In particular, the company focused on the wiring technology in semiconductor packaging technology, and conducted research and development on adopting thick copper wire capable of supporting higher voltages and larger currents to replace the thick aluminum wire that is currently the mainstay wiring material for power devices. However, because it has generally been technically difficult to mitigate chip damage when directly placing thick copper wire on aluminum electrodes, this was an obstacle for mass production.

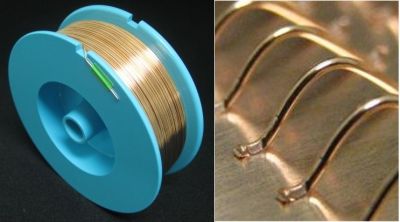

Upon introduction of the thick copper wire, New Japan Radio worked with Tanaka Denshi Kogyo and equipment manufacturer Ultrasonic Engineering Co., Ltd. to utilize wedge bonding technology (*3) to succeed in directly placing thick copper wire with a wire diameter of over 200 micrometers (a micrometer is a millionth of a meter) onto the aluminum electrodes of semiconductor chips, and established this as a mass production technology. Tanaka Denshi Kogyo's "CHA" thick copper wire used by New Japan Radio was released in January 2012 as a replacement for the thick aluminum wire currently widely used as large-current semiconductor wiring material for power devices. Tanaka Denshi Kogyo can practically implement copper wire for power devices by using its special processing equipment and annealing equipment to enable the uniform placement of microcrystal grain, which had been difficult in simple copper wire processing.

The melting point of aluminum is low at 660 degrees Celsius, and it sometimes fuses due to large currents. Moreover, as copper has a higher electric resistance than aluminum, CHA can raise the electrical conductivity by approximately 40% compared to aluminum of the same wire diameter.

Features of the mass production technology

1. High reliability; able to reach over 5,000 cycles in temperature cycling tests

Industrial equipment and EVs need to guarantee operation at high temperatures, and more demanding temperature cycling test (*4) life than present is required. The results of temperature cycling tests by New Japan Radio confirmed that copper wire has a product life of over 5,000 cycles compared to 2,000 cycles of aluminum wire.

2. Contribution to reduction of the burden on the environment by reducing the use of the material

Because copper wire has a higher fusing point than aluminum wire and is possible to obtain the characteristics of aluminum wire with a wire diameter of 300 micrometers using copper wire with a wire diameter of 200 micrometers, the amount of material used can be reduced, which contributes to reducing the burden on the environment. Furthermore, whereas the thermal conductivity of aluminum is 238W/mK, the thermal conductivity of copper is higher at 397W/mK, enabling it to be used as a low-loss technology due to its excellent exoergic properties.

New Japan Radio will primarily apply this technology to power devices, and will actively conduct product development. Tanaka Denshi Kogyo would like to contribute continuously to the advancement of development of the technology as a good business partner of New Japan Radio.

Company release:

http://www.acnnewswire.com/clientreports/513/529-1_EN.pdf

*1 Tanaka Denshi Kogyo K.K.

A company manufacturing bonding wire in the Tanaka Precious Metals Group, with TANAKA HOLDINGS Co., Ltd. as its holding company.

*2 Thick copper wire with a wire diameter of 200 micrometers or more used as a mass-production bonding technology for aluminum electrodes (survey by New Japan Radio as of May 2012).

*3 Wedge bonding technology

A wire bonding method in which bonding wire is directly connected to electrodes using ultrasound heat, etc., without forming a ball at the tip of the bonding wire.

*4 Temperature cycling test

A test for confirming that semiconductor products will not break or damage by repeatedly changing the ambient temperature.

Tanaka Holdings Co., Ltd. (Holding company of Tanaka Precious Metals)

Headquarters: 22F, Tokyo Building, 2-7-3 Marunouchi, Chiyoda-ku, Tokyo

Representative: Hideya Okamoto, President & CEO

Founded: 1885

Incorporated: 1918

Capital: 500 million yen

Employees in consolidated group: 3,456 (FY2010)

Net sales of consolidated group: 891.0 billion yen (FY2010)

Main businesses of the group: Manufacture, sales, import and export of precious metals (platinum, gold, silver, and others) and various types of industrial precious metals products. Recycling and refining of precious metals.

Website: http://www.tanaka.co.jp (Tanaka Precious Metals), http://pro.tanaka.co.jp (Industrial products)

Tanaka Denshi Kogyo K.K.

Head office: 22F Tokyo Building, 2-7-3 Marunouchi, Chiyoda-ku, Tokyo

Representative: Yasushi Kasahara, President & CEO

Incorporated: 1961

Capital: 1,880 million yen

Employees in consolidated group: 124 (FY2010)

Net sales of consolidated group: 36,37 billion yen (FY2010)

Businesses: Manufacture of high-purity bonding wire (gold, gold alloy, aluminum, aluminum-silicon, copper, etc.)

Website: http://www.tanaka-bondingwire.com/

About the Tanaka Precious Metals

Established in 1885, the Tanaka Precious Metals has built a diversified range of business activities focused on the use of precious metals. On April 1, 2010, the group was reorganized with Tanaka Holdings Co., Ltd. as the holding company (parent company) of the Tanaka Precious Metals. In addition to strengthening corporate governance, the company aims to improve overall service to customers by ensuring efficient management and dynamic execution of operations. Tanaka Precious Metals is committed, as a specialist corporate entity, to providing a diverse range of products through cooperation among group companies.

Tanaka Precious Metals is in the top class in Japan in terms of the volume of precious metal handled, and for many years the group has developed and stably supplied industrial precious metals, in addition to providing accessories and savings commodities utilizing precious metals. As precious metal professionals, the Group will continue to contribute to enriching people's lives in the future.

The eight core companies in the Tanaka Precious Metals are as follows.

- Tanaka Holdings Co., Ltd. (pure holding company)

- Tanaka Kikinzoku Kogyo K.K.

- Tanaka Kikinzoku Hanbai K.K.

- Tanaka Kikinzoku International K.K.

- Tanaka Denshi Kogyo K.K.

- Electroplating Engineers of Japan, Limited

- Tanaka Kikinzoku Jewelry K.K.

- Tanaka Kikinzoku Business Service K.K.

Japan Radio Co., Ltd.

Head office: 3-10, Nihonbashi Yokoyama-cho, Chuo-ku, Tokyo

Representative: Ryo Ogura, Representative Director & President

Established: 1959

Capital: 5.2 billion yen (as of March 31, 2011)

Employees: 3,116 consolidated, 1,547 non-consolidated (as of March 31, 2011)

Sales: 45.6 billion yen consolidated, 34.7 billion yen non-consolidated (year ended March 2011)

Businesses: Manufacture and sale of semiconductors, microwave tubes and peripherals, and microwave application products

Website: http://www.njr.co.jp/

Press inquiries

Global Sales Dept., Tanaka Kikinzoku International K.K. (TKI)

e-mail: tki-contact (at) ml.tanaka.co.jp

Topic: Press release summary

Source: TANAKA PRECIOUS METAL GROUP Co., Ltd.

Sectors: Metals & Mining, Daily Finance

https://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2025 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

|